100% Renewable Energy Operations

Leading the industry in environmental stewardship through sustainable manufacturing practices and zero-emission production.

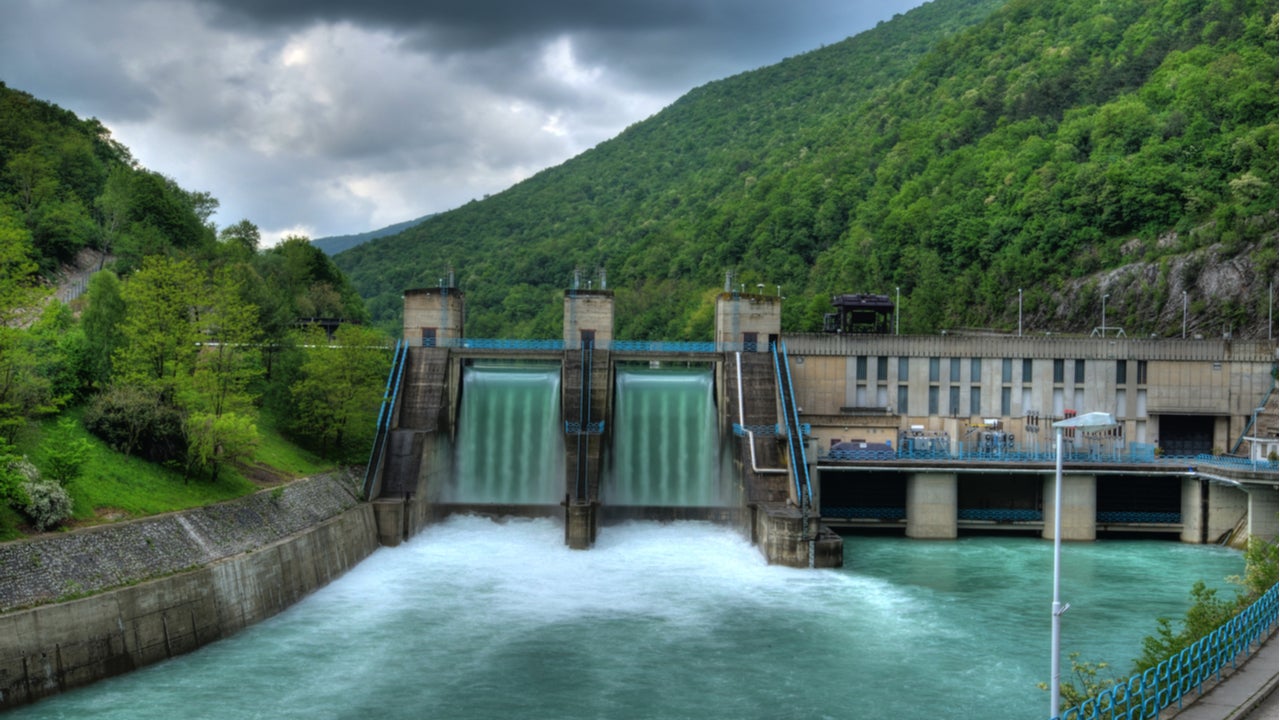

Hydroelectric Power

Our entire operation is powered by clean hydroelectric energy sourced from Washington State's abundant water resources. With 8MW of secured capacity at just 3¢/kWh, we've achieved both environmental sustainability and economic efficiency.

This renewable energy infrastructure is expandable, supporting our scaling strategy from 1 furnace to 9 furnaces without compromising our zero-carbon commitment.

Environmental Impact

Our commitment to sustainability delivers measurable environmental benefits across every aspect of production.

Zero Emissions

Our plasma-assisted electric melting process produces zero combustion emissions, eliminating CO₂, NOx, and other greenhouse gases.

Energy Efficiency

Plasma technology consumes 75% less energy than traditional gas-fired furnaces, dramatically reducing our environmental footprint.

Sustainable Materials

Basalt rock is an abundant natural resource that requires minimal processing, and our products are 100% recyclable.

Leading the Way in Green Manufacturing

Compared to traditional basalt fiber production methods, RoyalForge.Tech's approach delivers superior environmental performance:

ESG Leadership

Our operations align with Environmental, Social, and Governance (ESG) best practices, making RoyalForge.Tech an ideal partner for sustainability-focused organizations.

Zero-emission manufacturing, 100% renewable energy, sustainable materials sourcing

51% Alaska Native-owned, American job creation, community partnership, SDB certified

Transparent operations, quality standards compliance, ethical business practices

Net-Zero Carbon Manufacturing

By leveraging 100% hydroelectric power and efficient plasma technology, RoyalForge.Tech operates with a net-zero carbon footprint, setting a new standard for sustainable advanced materials manufacturing.